What is Polyethylene Terephthalate? General Article to Learn

Polyethylene terephthalate, often abbreviated as PET, might sound like a complex scientific term thrown around in industry conversations. while what is polyethylene terephthalate exactly? This fascinating material is more prevalent than most realize, seamlessly integrating into various facets of our daily lives. Found in unexpected places, from the packaging of your favorite beverages to the fibers composing your clothing, PET serves as a versatile polymer. Its exceptional properties and adaptability have led to its widespread use across diverse industries, driving innovation in manufacturing, sustainability efforts, and consumer convenience. Delving deeper into PET unveils not just its chemical composition, but also its multifaceted applications that shape the world we live in. So, what is pet plastic as a ubiquitous material, and how does it impact our lives? Keep on reading this article, you will find out the answer.

What Is Polyethylene Terephthalate in Our Daily Life?

Polyethylene terephthalate, commonly known as PET or PETE, boasts a diverse array of applications, primarily thriving in the domain of packaging materials for food products. Its lightweight nature, transparent quality, and available color variations make it an ideal choice for containers housing fruits and beverages. Functionally, PET stands out as a member of the ester family, earning it the moniker "polyester." This recyclable thermoplastic polymer exhibits remarkable traits including robust strength, ductility, stiffness, and hardness. These exceptional properties enable PET to undergo various manufacturing processes such as vacuum forming, injection molding, compression molding, and blow molding, facilitating its usage in creating a wide range of products beyond food packaging. From textiles to automotive components, and from industrial strapping to medical devices, PET's versatility and adaptability continue to revolutionize numerous industries, demonstrating its indispensability in modern manufacturing and daily life.

How Is Polyethylene Terephthalate Made?

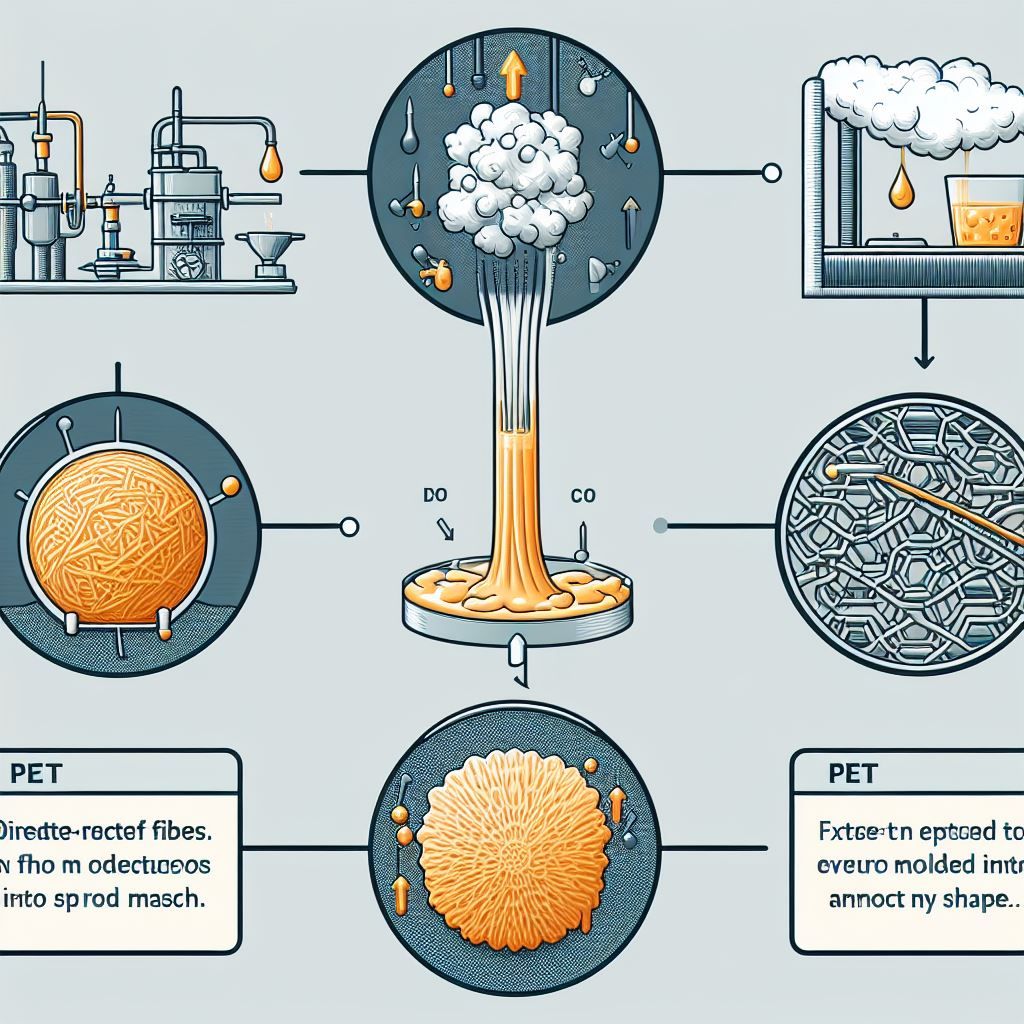

Polyethylene terephthalate, commonly known as PET, undergoes a meticulous manufacturing process through polycondensation reactions.

Preparation of Monomers: Obtain monomers through either:

Esterification reaction between terephthalic acid and ethylene glycol.

Trans-esterification reaction between ethylene glycol and dimethyl terephthalate.

Reaction Process: Combine dimethyl terephthalate or terephthalic acid with ethylene glycol in the chosen reaction. This process yields PET as a molten, highly viscous mass.

Polymerization: The chemical reaction forms the polymeric chain structure of PET through polymerization, creating a molten material that's highly versatile.

Molding and Shaping: Utilize the molten PET material directly, allowing it to be spun into fibers or extruded and molded into a wide variety of shapes and forms.

Characteristics of Polyethylene Terephthalate

Polyethylene terephthalate has impressive characteristics, which makes it a standout material across various industries. With its high strength and stiffness, PET offers exceptional durability. Its remarkable electrical insulating properties add to its versatility while being notably lightweight. PET's efficiency is further amplified by its superb gas and moisture barrier capabilities, effectively protecting contents. Operating within a wide temperature range, from -60 to 130 °C, PET demonstrates adaptability in diverse environments. Notably, its low gas permeability, especially with carbon dioxide, enhances its utility in multiple applications.

PET excels in transparent applications, particularly when rapid cooling or quenching is required during processing. Renowned for its resilience, PET resists breakage or fracturing, showcasing its shatterproof nature. Moreover, its recyclability underscores its eco-friendly attributes. An additional advantage lies in PET's transparency to microwave radiation, adding to its appeal in various consumer applications.

Applications of Polyethylene Terephthalate

Polyethylene terephthalate, whether in its virgin form or as recycled PET (rPET) flakes, finds versatile applications across various industries. rPET flakes are utilized in a multitude of ways, serving as an eco-conscious alternative while maintaining the properties and functionality of virgin PET. These applications include:

Fiber Products: Used in the production of carpets, fleece jackets, comforter fillings, and tote bags, offering both durability and sustainability.

Packaging Containers: Employed in the creation of containers for food, beverages (bottles), and non-food items, providing secure and eco-friendly packaging solutions.

Automotive Industry: Utilized for various automotive parts like carpets, sound insulation, boot linings, and seat covers, ensuring resilience and environmental consciousness in vehicle manufacturing.

Film and Sheet Production: Applied in creating films and sheets for multiple purposes, benefiting from PET's strength and flexibility.

Strapping: Utilized in strapping applications, ensuring robust and reliable packaging and transport solutions.

Industrial End-Use Items: Employed in the production of geotextiles and roof insulation, providing durable and sustainable materials for construction and industrial purposes.

Is Polyethylene Terephthalate Recyclable?

Is polyethylene terephthalate (PET) a recyclable material? Absolutely. PET, identified by its recycling code #1, is entirely recyclable and stands as one of the most widely recycled plastics globally. Offering a range of advantages such as lightweight, durability, and versatility, PET remains a preferred polymer in both the packaging and textile sectors. Despite its widespread usage, PET products often have a short lifespan, leading to a significant amount of waste. Consequently, recycling PET becomes a primary focus due to its potential for reuse. Its low diffusion coefficient enhances its suitability for recovery and recycling processes.

How Is Polyethylene Terephthalate Recyclable?

The process of recycling post-consumer PET bottles involves meticulous steps. These bottles are collected and subjected to specialized washing processes or undergo chemical treatment. These procedures effectively break down PET into its raw materials or intermediate forms, which are then utilized to produce recycled PET (rPET) flakes. The advancements in bottle recycling have spurred the development of innovative processing technologies, enhancing product purity while simultaneously reducing operational costs. This growing emphasis on bottle recycling underscores the continual evolution of recycling techniques for PET, ensuring a sustainable and efficient approach to managing this widely used material.

Conclusion

Polyethylene terephthalate (PET) stands as a versatile and essential material woven into various facets of daily life. Its exceptional properties drive its widespread use across industries, from packaging to automotive parts, demonstrating resilience, transparency, and recyclability. PET's recyclability, marked by its code #1, remains pivotal for sustainability efforts. Advancements in recycling techniques emphasize a promising path towards efficient PET management, underlining its enduring significance in modern manufacturing and its integral role in shaping a more sustainable world. Looking for more PET information at Wankai PET plastic supplier