PET's Rise as an Engineering Marvel

Polyethylene terephthalate, known commonly as PET, is no longer just the plastic your water bottle is made of. It's now at the forefront of innovative engineering applications, and the data backs it up. The global PET market size, valued at USD 25.25 billion in 2020, is expected to expand at a compound annual growth rate (CAGR) of 4.7% from 2021 to 2028. This growth reflects PET's versatility and rising popularity as an eco-friendly alternative.

Why PET?

PET's journey from a disposable packaging option to a sought-after engineering material is a tale of transformation. As the clarion call for sustainability grows louder, PET is emerging as a material that can be recycled and repurposed multiple times without significant degradation in quality. This recyclability is a game-changer, offering a greener footprint for industries looking to cut down on waste and reduce environmental impact.

Beyond Bottles

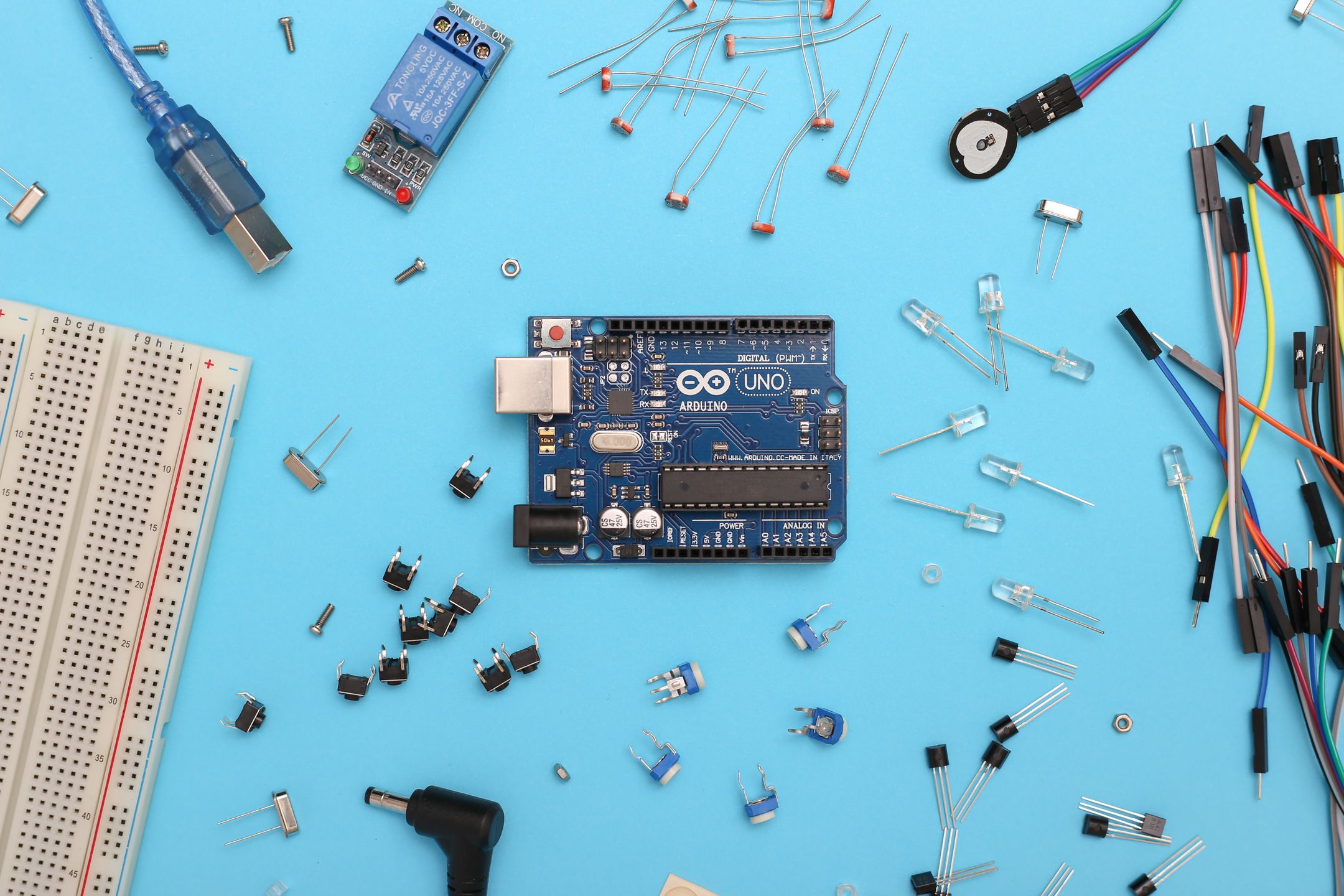

Gone are the days when PET's utility was confined to the beverage industry. Today, PET is a star performer across various sectors. In the automotive industry, PET components are lauded for their durability and lightweight nature, contributing to enhanced fuel efficiency and reduced emissions. In electronics, PET's excellent insulating properties are harnessed in components that demand high-performance and reliability.

In the textile sector, PET fibers are revolutionizing the market with their resilience and versatility. Known as polyester when used in fabrics, PET's applications range from fashion to industrial safety gear, offering a blend of comfort and durability that few materials can match.

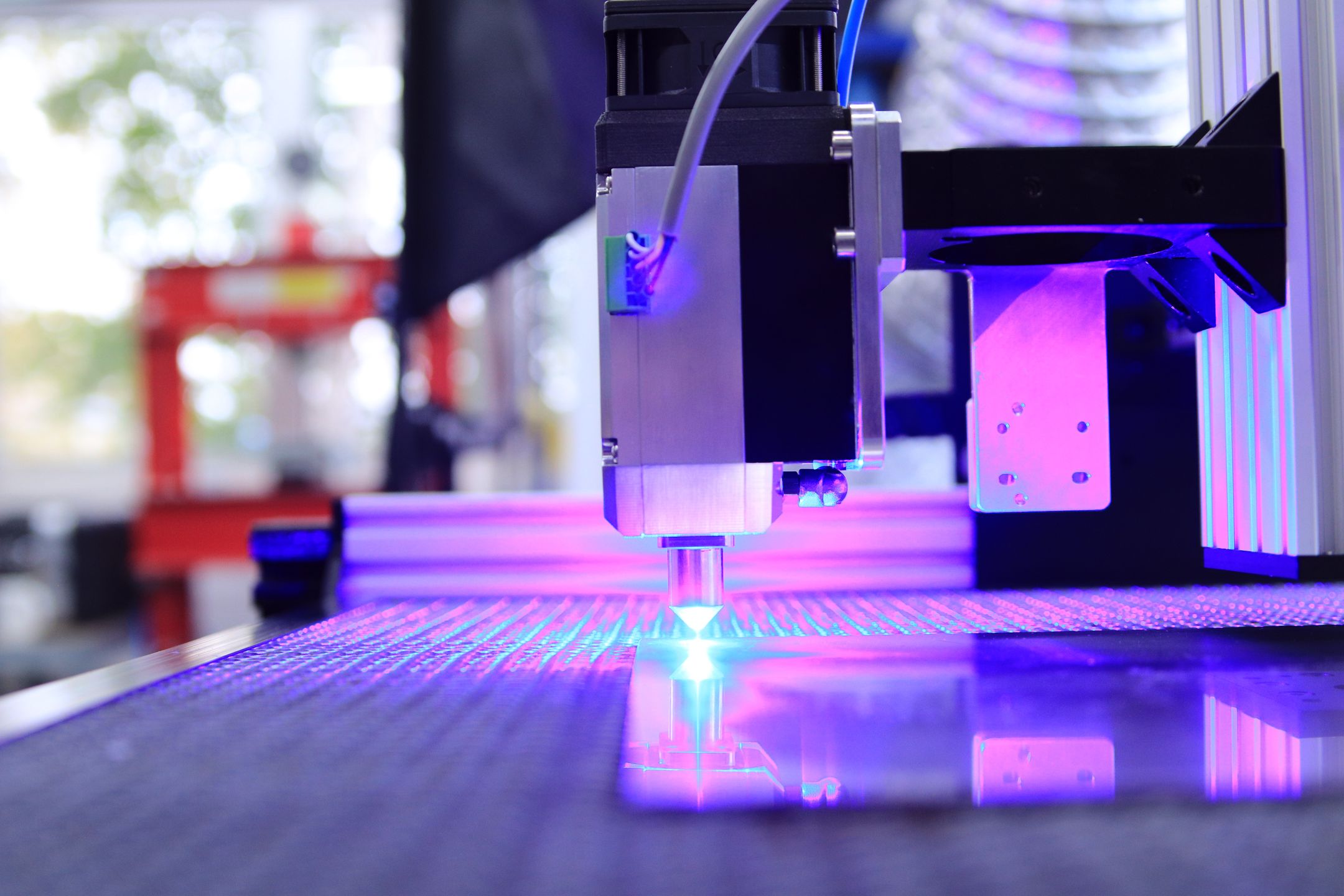

PET's Role in 3D Printing

The world of 3D printing is where PET truly shines as an engineering marvel. With its excellent thermal characteristics, PET is a preferred filament in 3D printing, allowing for the creation of intricate designs that are both strong and flexible. This has opened up possibilities for rapid prototyping and custom manufacturing, bringing down costs and lead times in product development.

The Future of Construction

One of the most exciting developments is PET's role in construction. Engineered PET structures are being explored for their resilience and thermal insulation, making them ideal for energy-efficient buildings. With the construction industry's ongoing quest for materials that contribute to green building certifications, PET's recyclability and energy-saving attributes are placing it firmly on the map of future building materials.

A key driver behind PET's popularity is its cost-effectiveness. While offering comparable, if not superior, performance attributes to more traditional materials, PET remains economically attractive. This balance of affordability and quality is encouraging more industries to adopt PET in their engineering solutions, leading to more innovation and enhanced applications.

The road to PET's dominance is not without its challenges. Concerns around the sourcing of raw materials and the need for efficient recycling systems are critical issues that the industry must address. However, these challenges also present opportunities for innovation in PET processing and lifecycle management, ensuring that the material's growth is sustainable in every sense of the word.

PET as the Material of Tomorrow

PET's role as a novel engineering material is just beginning to unfold. With its exceptional qualities and potential for eco-friendly engineering solutions, PET stands as a beacon of innovation in the material sciences. As industries and consumers alike push for more sustainable practices, PET's applications are set to widen, solidifying its place as a key player in the engineering material arena.

The shift towards PET is more than a trend; it's a testament to the ingenuity of modern engineering and a hopeful glimpse into a more sustainable future. As we continue to explore and expand the applications of PET, one thing is clear: this is a material that not only meets the demands of today but paves the way for the innovations of tomorrow.