5G Factory: Wankai's Pioneering Step into Manufacturing's Bright Future

The Relevance of 5G in Modern Manufacturing

The role of 5G technology in smart factories is to drive the manufacturing industry towards higher efficiency, flexibility, and intelligence. It provides the necessary network infrastructure for the integration of advanced manufacturing processes and cutting-edge technologies, enabling factories to better adapt to market changes, improve production efficiency, and enhance product quality.

Industry 4.0 refers to the combination of traditional manufacturing processes with advanced information and communication technology (ICT) to achieve digitalization and automation of factories and production. 5G technology can provide the network infrastructure needed to realize the Industry 4.0 vision in manufacturing. It can address the challenges faced by traditional manufacturing systems and bring about higher efficiency, flexibility, and intelligence.

Here are some key roles of 5G in smart factories:

1. Enabling high-performance Industrial Internet of Things (IIoT):

2. Supporting advanced automation and robotics technology:

3. Applications of Augmented Reality (AR) and Virtual Reality (VR):

4. Implementing predictive maintenance and real-time data analysis:

5. Supporting remote operations and monitoring:

6. Promoting the integration of edge computing and cloud computing.

Chongqing Wankai's Focus on a 5G Factory

Based on the "5G+ Industrial Internet" fully connected factory construction guide, Chongqing Wankai has truly realized flexible production and refined management through the low latency, high reliability, and massive connectivity of 5G technology. This has provided a manufacturing environment that is responsive, resilient, and finely tuned, helping businesses reduce costs, meet delivery deadlines, improve product and service quality, and provide excellent enterprise information management. This supports Wankai in building a modern smart factory.

The company has formed a new organization, new products, and new models centered around intelligence in the packaging production field based on PET materials. By offering high-quality services, it promotes improvements in quality and efficiency and optimizes economic structure, boosting the reconstruction and upgrading of all elements, the entire industrial chain, and the entire value chain within the industry.

The Transformative Impact of 5G in Chongqing Factory

The integration of 5G technology has optimized production processes and fostered the deep integration of information technology (IT) and operational technology (OT), providing robust technical support for the creation of innovative and highly efficient smart factories.

In terms of business management and control, the capabilities of digital twins, such as real-time monitoring and precise fault location, have significantly reduced personnel workload and reduced the investment in labor costs for enterprises. This has also reduced the time taken to handle production anomalies (from an average of 2 hours to just 15 minutes), improving production efficiency.

In terms of information technology development, the adoption of advanced cloud platforms and microservices technologies, designed according to principles of high cohesion and low coupling, allows for the easy generation of applications through drag-and-drop methods, reducing repetitive investments in enterprise information technology development. Drones, 5G dual-light control balls, smart safety helmets, and AR glasses are all new products derived from 5G technology. Exploring how to integrate these new 5G smart products with industrial intelligent factories is a direction we have been investigating.

Here are some case studies:

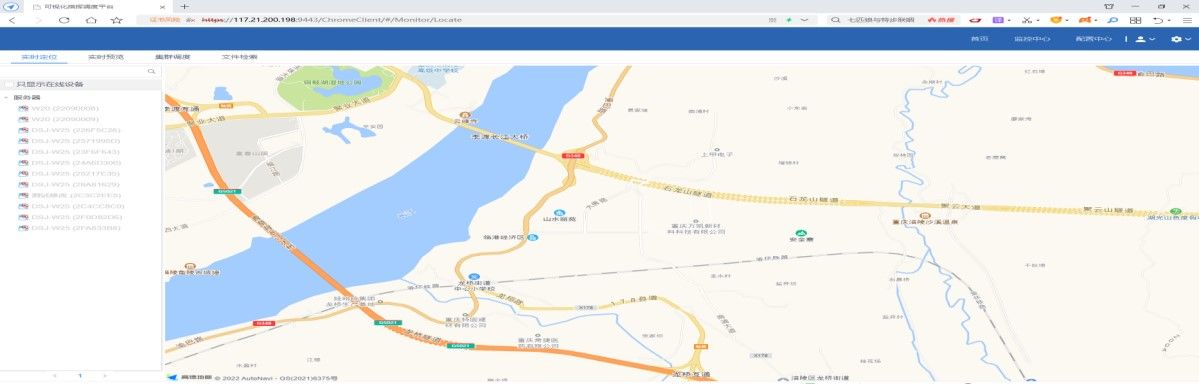

1. Production Site Monitoring: Install 1-2 5G dual-light control balls at key locations within the factory. These control balls connect to the 5G base station for video transmission, enabling real-time monitoring of various areas within the factory.

2. Infrared Fault Monitoring: Install a 5G dual-light control ball and a thermal imaging camera at critical points of production equipment to collect temperature information in real-time for leak detection.

3. Inspection Monitoring and Retransmission: Equip factory inspectors with smart safety helmets. The video retransmission feature of the helmet allows for real-time monitoring, and the recording function can document the inspection process for later review.

Image:Personnel Location with Smart Safety Helmet

4. Personnel Safety Monitoring: Equip maintenance personnel with smart safety helmets. The silent alarm function and SOS button of the helmet ensure the safety of maintenance staff.

The Broader Significance of a 5G Factory

Entering the era of Industry 4.0, manufacturing enterprises are faced with the challenges of personalized production and service-oriented transformation. Industrial Internet, as a product of the deep integration of the latest information technology and manufacturing, is essentially about achieving comprehensive interconnection among people, machines, and things, constructing a new industrial production and service system that is fully connected across all elements, the entire industrial chain, and the entire value chain. 5G, as the next-generation mobile communication system, with its low latency, high transmission capacity, and low cost of reliability, ensures that it can be integrated with all aspects of industry. It provides industrial enterprises with tools for flexible production and intelligent manufacturing and also offers means for industrial enterprises to connect with their users and supply chains, driving the industry towards intelligence, service orientation, and high-end advancement.

Chongqing Wankai aims to transform manufacturing enterprises from automation to digitization and intelligence using 5G, industrial Internet, and digital twin technology. They will explore deep value and strategic transformation, combining AI, machine learning, and deep learning to create a smart integrated factory.