WK-801: A Promising and Sustainable bottle-grade PET resin chips

Polyethylene terephthalate (PET) is a widely used material in our daily lives, as it can be found in numerous products. Its chemical formula is (C10H8O4)n, and it is classified as a crystalline saturated polyester. PET is manufactured as part of the petroleum chemical industry chain, using the main raw materials of PTA (purified terephthalic acid) and MEG (monoethylene glycol), both derived from petroleum. These raw materials undergo a process of condensation to produce PET chips, which serve as the basis for further applications.

The intended use and application determine the specific grade of PET required. In general, PET can be divided into bottle-grade PET, fiber-grade PET, and film-grade PET according to its application. For example, bottle-grade PET is the most commonly used grade and has the highest market demand. With the growing demand for bottled beverages and other packaged products, the production capacity for bottle-grade PET is continuously increasing to meet market needs.

In the current era, there's an escalating emphasis on safety, environmental protection, and green initiatives in the PET industry. This trend accentuates the integrated value of the PET industry chain, focusing on sustainable development and minimizing its carbon footprint. As a result, PET emerges as a promising, eco-friendly packaging material with a bright market outlook. Among the various PET grades, bottle-grade PET reigns supreme with the highest market demand, witnessing steady growth. In response to this demand, the production capacity for bottle-grade PET is expanding at a rapid pace, coupled with a concurrent surge in capacity utilization.

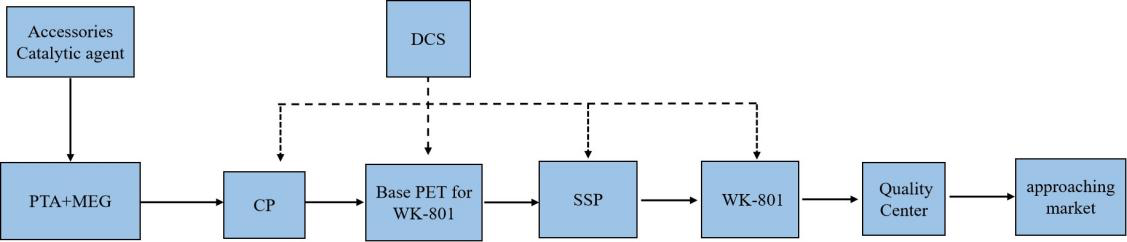

Among the renowned bottle-grade PET offerings, the WK-801 produced by Wankai New Materials Co., Ltd., which necessitates a blend of liquid-phase and solid-phase polymerization processes, is widely used in the production of plastic water bottles. To meet the demands of the thriving production, these factories are equipped with cutting-edge machinery, including the continuous poly-condensation units designed by the renowned China Kunlun Contracting & Engineering Corporation, which reaches internationally advanced level. Moreover, they have integrated the solid state polymerization patented equipment developed by the prestigious Switzerland BUHLER into the production process. To ensure smooth operations, Wankai utilize the state-of-the-art DCS central control system, developed by Honeywell, which enables relevant departments to monitor the entire production process.

Once the production of the WK-801 is complete, the dedicated Quality Center of Wankai diligently carries out random inspections to ensure the product's superior quality. Guided by the principles of fairness, scientific accuracy, and efficiency, the Quality Center meticulously manages the quality of the company's products and systems. Wankai unwavering adherence to the ISO 9001 quality management system guarantees that every aspect of product research and development, production, and services is strictly regulated. To further strengthen the quality culture, Wankai have implemented a host of management tools and systems, including QCC (Quality Control Circles), the 6S (a method for workplace organization), and TPM (Total Productive Maintenance).

The production process of WK-801 epitomizes Wankai's unwavering commitment to prioritizing quality and their scientific and effective management of product research and development, production, and services. This commitment embodies their aspirations to establish themselves as a global leader in polyester products, reflecting Wankai's dedication to achieving the highest standards of excellence.

In 2008, Wankai New Materials Co., Ltd. was born, a global leader in bottle-grade PET located in the thriving Yangtze River Delta region of China. Wankai is committed to providing healthy, safe, eco-friendly, and high-quality materials to society, and has earned a good reputation. With an annual production capacity of 3 million tons, Wankai stands fourth globally and second in China. Its products are exported domestically and internationally, adopted by global renowned companies such as Danone, Coca-Cola, Nestlé, and others. Its products have been met with resounding applause from both domestic and international customers due to the exceptional equipment and advanced technology utilized by the esteemed company.