What is BoPET Film and How is it Made from PET?

BoPET (Biaxially Oriented Polyethylene Terephthalate) film is a versatile plastic material known for its superior mechanical and physical properties, making it an essential component in a wide range of industrial and consumer applications. This blog will delve into what BoPET film is, its properties, uses, and the process of manufacturing it from PET (Polyethylene Terephthalate).

Understanding BoPET Film

BoPET film is created by stretching polyethylene terephthalate (PET) both in the machine direction (MD) and transverse direction (TD). This biaxial orientation gives the film remarkable strength, stability, and clarity. The film is extensively used in packaging, electronics, magnetic media, and insulation due to its excellent tensile strength, chemical and dimensional stability, transparency, reflectivity, gas and aroma barrier properties, and electrical insulation.

Key Properties of BoPET Film

BoPET film has high tensile strength, typically in the range of 150-200 MPa. It is resistant to a wide range of chemicals, including oils, greases, and many solvents. BoPET film can withstand temperatures up to 150°C. The film exhibits minimal shrinkage and maintains its dimensions under stress. It offers excellent transparency and surface gloss. BoPET film provides a strong barrier against gases and moisture.

Applications of BoPET Film

BoPET film is used in food and beverage packaging for its barrier properties. It is applied in flexible printed circuits, displays, and insulation materials in electronics. It is utilized in audio, video, and data storage tapes in magnetic media. BoPET film is employed in electrical insulation due to its dielectric properties.

Manufacturing Process of BoPET Film

The production of BoPET film from PET involves several steps:

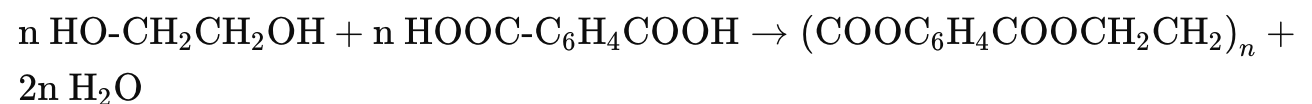

- Polymerization: The process begins with the polymerization of ethylene glycol (EG) and terephthalic acid (TPA) to produce PET. The reaction is typically conducted at high temperatures and in the presence of catalysts.

- Extrusion: The PET pellets are then melted and extruded into a thick film through a flat die.

- Casting: The extruded film is cast onto a chill roll to solidify it into an amorphous sheet.

- Biaxial Orientation: The amorphous PET sheet is then stretched biaxially—first in the machine direction (MD) and then in the transverse direction (TD). This biaxial stretching aligns the polymer chains, enhancing the film's mechanical and thermal properties.

- Heat Setting: The biaxially oriented film is heat-set to lock in the molecular orientation and eliminate internal stresses, resulting in a dimensionally stable film.

- Winding: Finally, the finished BoPET film is wound onto rolls for further processing or shipment.

Advantages of BoPET Film Production

Biaxial orientation significantly improves the film's properties, making it suitable for high-performance applications. BoPET film can be tailored to meet specific requirements by altering the stretching and heat-setting conditions. BoPET film is recyclable, contributing to sustainable packaging solutions.

Conclusion

BoPET film, with its outstanding mechanical, thermal, and barrier properties, plays a crucial role in various industries. The process of transforming PET into BoPET film through polymerization, extrusion, casting, biaxial orientation, and heat setting results in a versatile material that meets the demanding requirements of modern applications. Its durability, clarity, and resistance make it an indispensable material in packaging, electronics, and beyond.

By understanding the science and technology behind BoPET film, industries can better leverage its properties for innovative and efficient product solutions. For high-quality PET materials essential for producing superior BoPET films, Wankai provides industry-leading products that ensure reliability and performance in every application. Wankai’s PET is available in bottle grade PET and non-bottle grade PET forms, with the latter specifically designed for manufacturing high-quality BoPET films.