Wankai's Research & Development: An Advancing PET Waste Recycling System

The American Plastics Recycling Association (APR) has provided valuable data on the carbon emissions associated with the production of virgin PET resin compared to recycled PET resin. The considerable reduction in emissions from producing recycled PET resin underscores the importance of PET bottle recycling in mitigating the carbon footprint. It is imperative for the plastics industry to focus on improving the efficiency of PET bottle recycling and promoting the circular use of resources.

Under these circumstances, Wankai has introduced an innovative PET waste recycling technology that shows great potential in addressing industry challenges and contributing to environmental sustainability through a reduced carbon footprint and optimized resource utilization in plastic recycling.

1. How do the recycling system work?

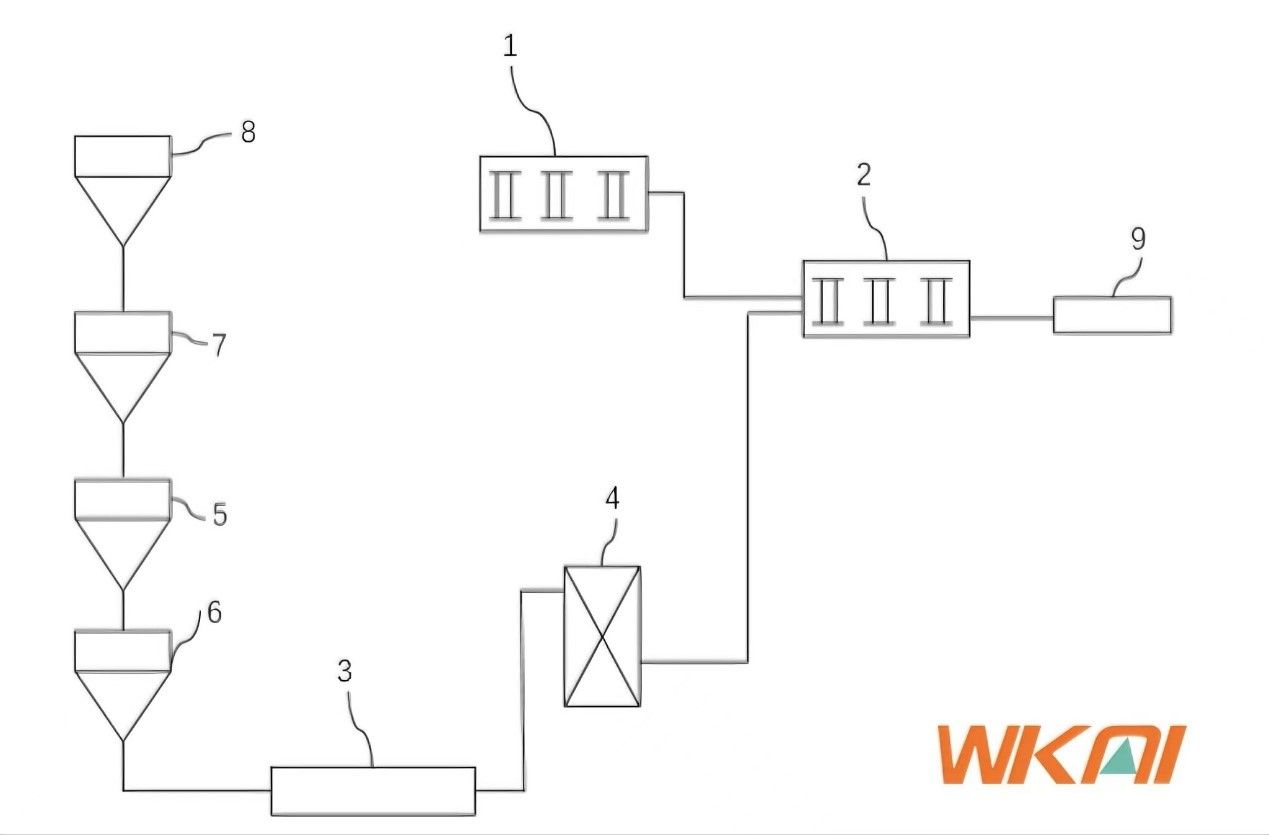

Wankai's PET recycling system employs a comprehensive process to transform waste PET into a high-quality, reusable form. These key steps are as follows:

Pretreatment: The waste PET is first washed, crushed, and screened (8) to prepare it for further processing.

Dehydration: The pretreated PET is then conveyed into a pre-dryer (7) and a drying tower (5) to remove impurities and moisture, with the hot air being recycled for efficiency.

Storage: The dried PET is stored in an insulated silo (6) until ready for the next stage.

Melting and Filtration: The PET is fed into a screw extruder (3) where it is melted, then filtered through a melt filter (4) to ensure purity.

Repolymerization: The molten, filtered PET is introduced into a final polymerization reactor (2), where it is combined with ethylene glycol and terephthalic acid to undergo repolymerization, forming new and high-quality PET.

Pelletization: Finally, the repolymerized PET is pelletized using a dedicated machine (9), ready for further processing and manufacturing.

2. What’s the innovative breakthrough of this recycling system?

Wankai' recycling equipment showcases an innovative approach to processing PET waste, particularly in the application of chemical recycling technology. Let's briefly understand two common methods for recycling PET waste: physical recycling and chemical recycling.

Physical recycling, also known as mechanical recycling, primarily involves washing, crushing, and screening PET waste to recycle it into terminal products.This method has strict requirements for raw material quality, separation, and purification operations to ensure the quality of the final product. In contrast, traditional chemical recycling is different. It uses special equipment to initially hydrolyze waste PET into ethylene glycol terephthalate (BHET) monomers and then repolymerizes them to produce a product of comparable quality to virgin polyester. Although this method can produce high-quality recycled products, its operation is relatively complex and its controllability is low.

However, chemical recycling has garnered significant attention for its advanced technology and promising future. It transforms PET waste into valuable raw materials, fostering circularity and supporting PET recycling and reuse. Wankai's recycling system falls under this category, and its design shines through in its streamlined operation. Unlike traditional methods, it omits the pre-degradation step, thus circumventing potential side reactions, boosting material efficiency, and safeguarding the quality of polyester products. This approach not only conserves energy but also enhances the economic viability of the enterprise, aligning with the principles of resource conservation and sustainable development.

Conclusion

Wankai's PET recycling system represents a substantial step forward in the plastics industry's quest for sustainability and circularity. By enhancing the quality of recycled PET while cutting costs, the system sets the stage for a more efficient and sustainable PET recycling process. In the future, we look forward to even greater breakthroughs in the recycling and utilization of PET waste, as the plastics industry continues its journey towards greater sustainability.