Wankai Deepens Cooperation with Linker Hand: Precision Injection Molding Division Enables Scaled “Plastic-to-Steel” Substitution in Robotics

Amid the rapid rise of the robotics industry, material innovation and manufacturing upgrades are becoming the key drivers of technological breakthroughs. Recently, ZheJiang KaiPuQi New Materials Technology Co., Ltd., a wholly-owned subsidiary of Wankai New Materials Co., Ltd., announced the establishment of a Precision Injection Molding Division dedicated to producing core plastic components for Linker Hand (Beijing) Technology Co., Ltd. This initiative not only elevates the partnership between the two companies but also marks a major step toward the professional and large-scale application of “plastic-to-steel” technology in robotics.

From Material R&D to Manufacturing Implementation

The collaboration between Wankai New Materials and Linker Hand has been steadily advancing. On June 16, both parties jointly established a High-Performance Materials Laboratory, achieving breakthroughs in the development of phenolphthalein-based polyaryletherketone (PEKC) and other high-performance composite materials. These advanced materials, featuring superior weight reduction and toughness compared to conventional metals, have laid a solid foundation for the application of “plastic-to-steel” solutions in robotic components.

The newly established Precision Injection Molding Division is a key extension of this partnership—from material research to manufacturing delivery. Building on continuous material modification efforts, the division will provide end-to-end support for Linker Hand's “plastic-to-steel” structural components, covering mold design, precision production, and injection molding. This integrated approach accelerates the transformation of scientific research achievements into industrial applications.

Linker Hand: Industry Leader with Expanding Applications

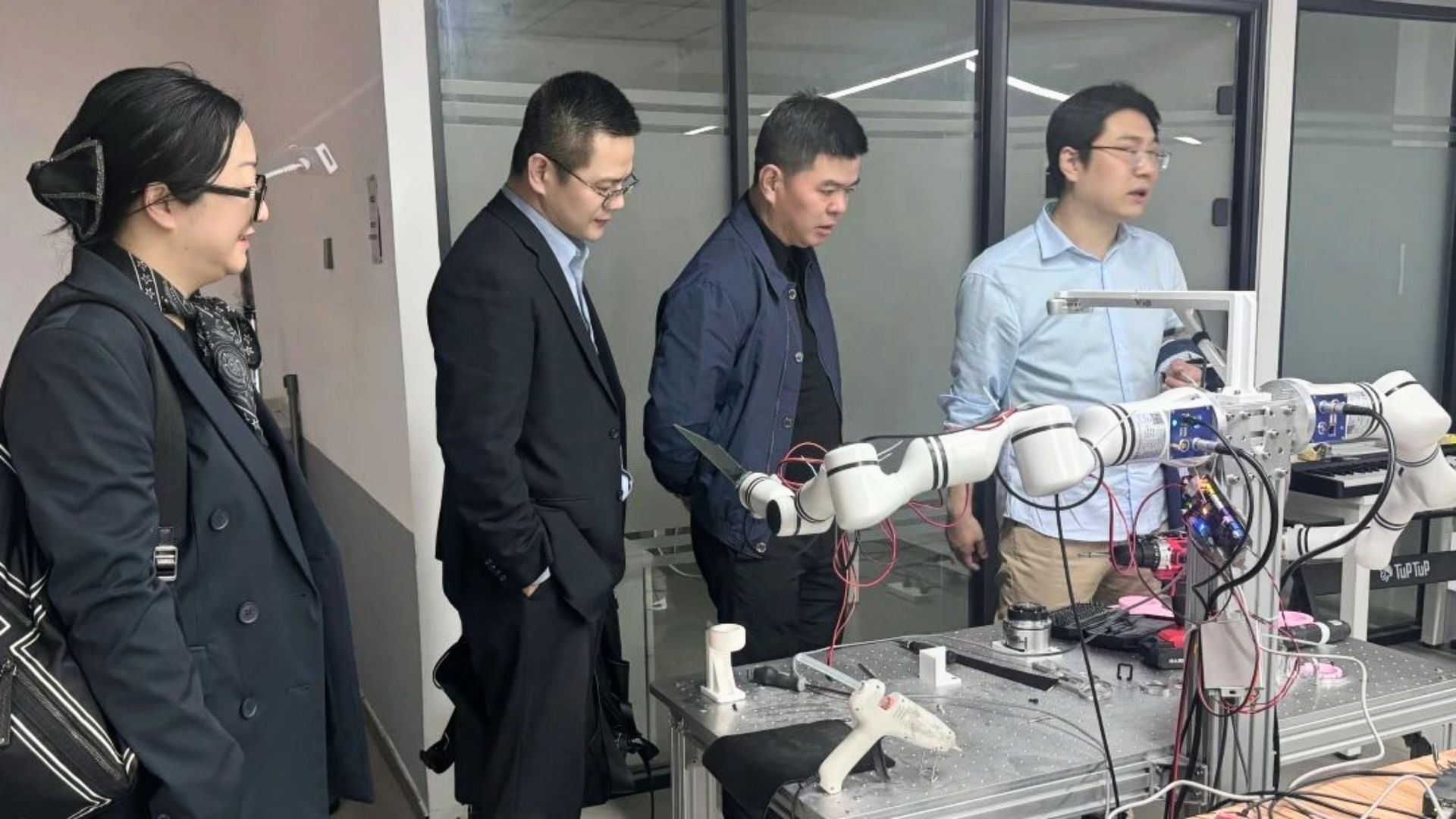

Linker Hand is a global leader in high-degree-of-freedom dexterous hands, with its Linker Hand series receiving more than 1,000 monthly orders, maintaining a leading position in the industry. Its products are widely applied in scientific research, medical assistance, and industrial automation.

The company has also gained strong recognition from both capital markets and authoritative media—with investment support from Ant Group and Sequoia Capital, and recent praise from People’s Daily for its technological innovation. Meanwhile, Linker Hand is actively expanding its application scenarios, with its next-generation “Industrial Master” dexterous hand entering pilot verification, unlocking new market opportunities. This rapid development places higher demands on core component supply capacity and customization—creating a timely opportunity for deeper collaboration.

Strengthening Injection Molding Capabilities: Building Dual Competitive Advantages

To ensure stable supply and improved quality of Linker Hand’s core components, Wankai New Materials is making strong investments in precision injection molding. The new division has assembled an industry-leading expert team, many of whom have over 10 years of experience in precision and micro-injection molding—capable of meeting complex structural and high-precision part requirements.

In parallel, Wankai New Materials is implementing a “investment + industrial development” dual-drive model:

- Internal enhancement: Establishing a 7×24 rapid response system that delivers customized solutions within 48 hours and completes sample delivery within 7 days.

- External integration: Exploring potential investments in high-quality precision injection molding companies, leveraging resource integration and technological synergies to further strengthen core competitiveness.

Accelerating “Plastic-to-Steel” in Robotics

As the full-chain ecosystem of high-performance materials development – precision injection molding – high-end robotic applications continues to mature, the collaboration between Wankai New Materials and Linker Hand will inject greater innovation momentum into China’s humanoid robotics industry. Together, they aim to accelerate the scaled application of “plastic-to-steel” technology in robotics, enabling Chinese-made robots to compete more effectively on the global stage.