Qingmei Zhisu & Linkerbot Jointly Launch New Product: PEEK Cycloidal Reducer

Rooted in Materials, Dedicated to Intelligent Manufacturing

With the mission of "making materials lighter and manufacturing smarter," Qingmei Zhisu leverages its parent company's strong foundation in global materials science to focus on cutting-edge embodied robotics. It delivers integrated lightweight solutions for dexterous hands, robotic arms, and robot bodies, guided by the principles of "lighter, stronger, and more precise."

Its core competitiveness lies in four key capabilities:

1. Material Selection and Customized R&D

Mastery of a full spectrum of materials ranging from general plastics to high-performance engineering plastics, enabling optimized material selection and customized formulations for robotic joints, dexterous hands, housings, sensors, and other components with specific mechanical, thermal, and chemical resistance requirements.

2. Design and Simulation Capabilities

A professional simulation team utilizing tools such as ANSYS and Altair to conduct structural, dynamic, thermal, and multi-physics simulations at the design stage, achieving dual breakthroughs in structural reliability and lightweight performance.

3. Precision Injection Molding and Intelligent Manufacturing

A fully digitalized intelligent injection molding workshop equipped with internationally advanced precision molding equipment, intelligent temperature control systems, and online inspection systems, enabling 0.1 mm-level fine structure molding and high-yield mass production.

4. End-to-End Service Capability

A fully integrated industrial chain covering "material selection – design simulation – precision molding/machining – assembly – performance testing – mass delivery," allowing rapid response from prototyping to large-scale production and significantly shortening time-to-market.

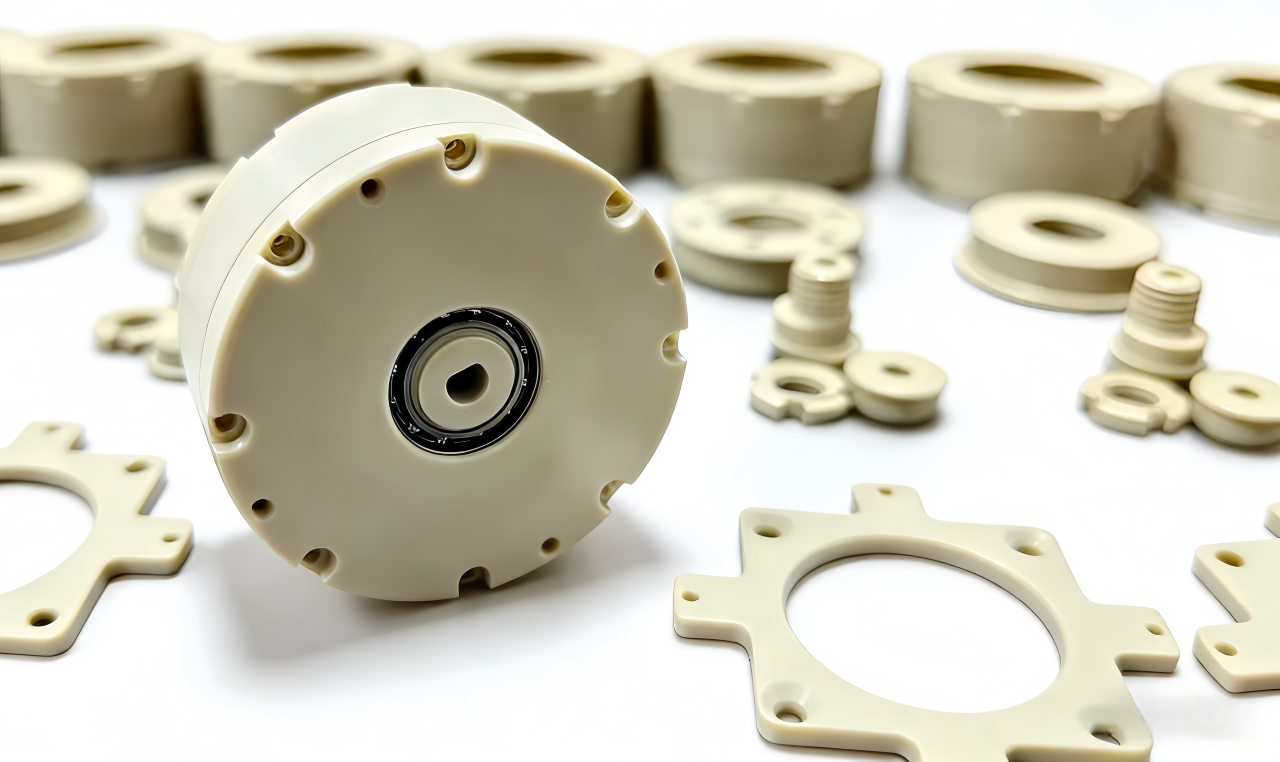

Replacing Steel with Plastics — Unlocking a Lightweight Future

Leveraging deep material expertise, Qingmei Zhisu, together with Linkerbot, has successfully introduced high-performance engineering plastic PEEK (Polyether Ether Ketone) into the main load-bearing structure of cycloidal reducers. This is far more than a simple material substitution. It represents a fundamental system-level redesign, with PEEK serving as a core load-transmitting structural material, redefining the internal architecture of the reducer.

This innovation delivers significant performance advantages:

- Substantial weight reduction: greatly lowers joint mass, improving power density and dynamic response.

- Low noise and vibration damping: inherent material damping effectively reduces operational noise and vibration, enhancing system stability.

- Self-lubricating and corrosion-resistant: reduces lubrication requirements and expands application scenarios in harsh environments.

- Integrated molding: complex structures formed in one piece through precision injection molding, reducing part count and improving overall reliability.

With this product, the value of PEEK is no longer measured by kilograms, but by joint performance. A single humanoid robot typically contains 20–30 joints. High-load positions such as hips, knees, shoulders, and elbows can all adopt this solution, opening broad opportunities for large-scale, multi-point application.

This launch represents not only a revolutionary reducer, but also an extensible technology platform. It marks the emergence of "high-performance materials + precision manufacturing" as a new paradigm for upgrading robotic core components.

Looking ahead, this innovation can be extended to collaborative robots, special-purpose robots, and high-end automation equipment, gradually forming a product matrix based on the integration of "materials × structure × load," continuously delivering lighter, stronger, and smarter solutions for the industry.

Lightweight Intelligent Manufacturing — Beyond Lightweight

This collaboration is not merely a product breakthrough, but the beginning of a new industrial pathway. Qingmei Zhisu will continue to work with ecosystem partners to drive material innovation and manufacturing upgrades for robotic core components. We believe this marks a new starting point for the evolution of robotic core components toward lighter weight, higher strength, and better adaptation to real-world operating conditions.